Graduate School of Science and Engineering Mechanical Engineering

- Course Outline

- Metallic Materials Science Laboratory

- Applied Materials Engineering Laboratory

- Advanced Materials Structural Engineering Laboratory

- Spray and Combustion Science Laboratory

- Heat Transfer Laboratory

- Laboratory of Fluid Mechanics

- Motion and Vibration Control Laboratory

- Manufacturing System and Design Laboratory

- Machine Elements and Tribology Laboratory

- Applied and Engineering Mathematics

- Physics Laboratory

Applied Materials Engineering Laboratory

Processing environmentally friendly metal and polymer materials

Staff

![Tatsuya TANAKA [Professor]](/istc/attach/page/TECHNOLOGY-PAGE-EN-46/25636/resize-file/staff_02.jpg)

TANAKA Tatsuya

[Professor]

| Acceptable course | |

|---|---|

| Master's degree course | ✓ |

| Doctoral degree course | ✓ |

Telephone : +81-774-65-6465

tatanaka@mail.doshisha.ac.jp

Office : YM-325

Database of Researchers

SASADA Masahiro

[Professor]

| Acceptable course | |

|---|---|

| Master's degree course | ✓ |

| Doctoral degree course | ✓ |

Telephone : +81-774-65-6556

msasada@mail.doshisha.ac.jp

Office : YM-324

Database of Researchers

Research Topics

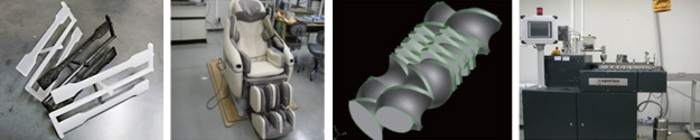

- Basic research on forming high-tensile steels for automobiles

- Research on improving heat-resistance and impact strengths for environmentally-conscious, natural long-fiber reinforced Poly Lactic Acid (PLA)

- Research on 3D, high-viscosity, thermohydraulic analysis in a twin-screw extruder

- Research on optimal weight minimization of massage chairs

- Research on forming resin foams for automobile aluminum honeycomb sheets

Research Contents

The Applied Materials Engineering Laboratory conducts research on materials processing.

The fields of research can be broadly categorized into (A) metal processing, (B) polymer processing, and (C)

applied materials processing. Research activities in these fields require a sound basic knowledge of viscoelastic

dynamics, plastic dynamics, continuum dynamics, and plastic processing. Whether using metals or polymers, the

major processing methods involve either exploiting high-strain-rate deformations or repeated deformations to

plastically process metals in solid form in a mold, or heating materials above their melting point and exploiting

the fluidity of the material to rapidly inject (cast) it under high pressure in a mold.

In addition to basic experiments to elucidate the deformation and flow mechanisms, we apply finite element method

(FEM) and difference method software (CAE analysis) to establish theories to assist engineering applications.

The basic philosophy of this laboratory is to conduct "research on forming environmentally friendly materials

(materials with low environmental burden)." While "environmentally friendly material" is difficult to define

strictly, research topics are selected according to keywords such as "Recycling," "Functionality," and

"Lightness," etc. However, industrial materials that match these keywords are not necessarily easy to process; in

fact, most such materials are difficult to process. Consequently, our research topics center on materials which

are significant from the material research viewpoint, but requires thorough research on the forming technologies

for their industrial application.

Keywords

- High-strain-rate plastic processing

- Shock wave

- Inelastic constitutive equation

- Incremental forming

- Semi-solid molding

- Nano-crystal

- Natural-fiber-reinforced plastic

- Carbon-fiber-reinforced plastic

- Injection molding

- Extrusion molding