Graduate School of Science and Engineering Mechanical Engineering

- Course Outline

- Metallic Materials Science Laboratory

- Applied Materials Engineering Laboratory

- Advanced Materials Structural Engineering Laboratory

- Spray and Combustion Science Laboratory

- Heat Transfer Laboratory

- Laboratory of Fluid Mechanics

- Motion and Vibration Control Laboratory

- Manufacturing System and Design Laboratory

- Machine Elements and Tribology Laboratory

- Applied and Engineering Mathematics

- Physics Laboratory

Manufacturing System and Design Laboratory

Website of the Laboratory 【In English】

On the website above, please choose the "Science and Manufacturing labs”→"Manufacturing System and Design

Laboratory", and you can find some information and Youtube movies.

Website of the Laboratory 【In Japanese】

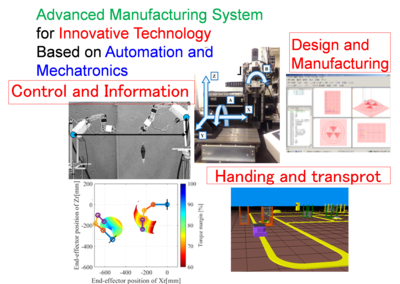

Manufacturing System and Design Technologies Based on Automation and Sustainability

Staff

HIROGAKI Toshiki

[Professor]

| Acceptable course | |

|---|---|

| Master's degree course | ✓ |

| Doctoral degree course | ✓ |

Telephone : +81-774-65-6503

thirogak@mail.doshisha.ac.jp

Office : YM-503

Database of Researchers

NAKAGAWA Masao

[Associate Professor]

| Acceptable course | |

|---|---|

| Master's degree course | |

| Doctoral degree course | |

Telephone : +81-774-65-6479

manakaga@mail.doshisha.ac.jp

Office : YM-502

Database of Researchers

Research Topics

- CAD/CAM, Industrial Robot and Machine Tool for automation technology

- Control of Automatic Guided Vehicle and Industrial Robots and Machine tools

- Factory Automation (FA) based on Mechatronics Technology

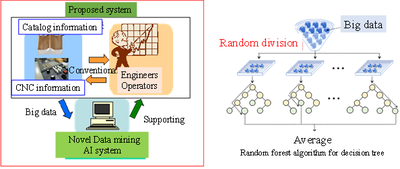

- Data Mining of Manufacturing and Machining Process Control Based on AI (artificial intelligence)

- Design and Quality Control of Gear Powertrain for Hybrid Vehicle and Electric Vehicle

- Dynamic Control and Monitoring of Process for Automation and Green Sustainable Manufacturing

Research Contents

We focus on automation and sustainable technology in the manufacturing fields, including novel product design, life cycle assessment, machine control, machining process control and computer aided manufacturing based on mechatronics and AI (artificial intelligence) technologies.

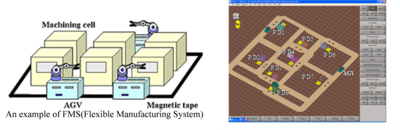

Construction of advanced and innovative manufacturing system

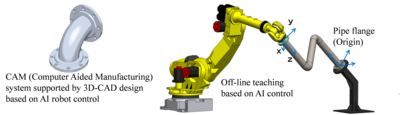

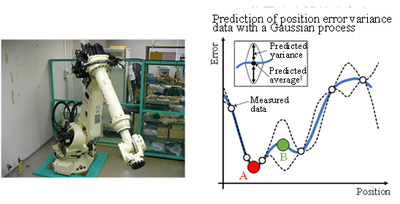

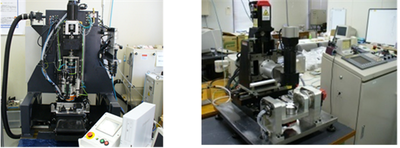

(1) CAD/CAM, Industrial Robot and Computer Numerical Control (CNC) Machine Tools Integrated System Based on

Automation Technologies

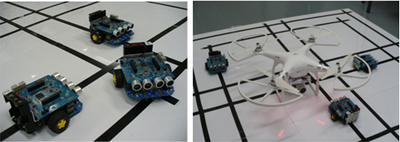

* Development of autonomous distributed and cooperated control for handling and transport technologies

* Development of integrated Robot motion control and CAD/CAM system supported by AI (artificial intelligence)

technologies

(Machine learning of skillful operations for off-line teaching of large size industrial robot)

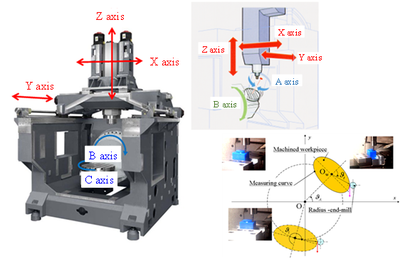

* Complex motion control for cutter location (CL) with five axis controlled machine tools

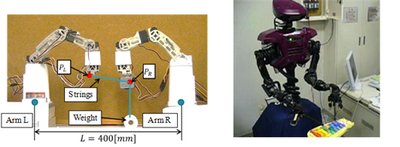

* Development of cooperative motion and operation control for various types of dual arm industrial robots and various sizes of industrial robots

* Advanced manufacturing system based on IoT (Internet of Things) and data mining

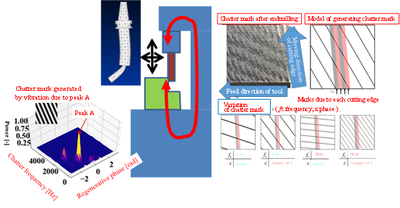

Image processing for machined surface to monitor and control a chatter vibration based on two-dimensional discrete Fourier transform

(2) Automation for traditional skill and sustainable manufacturing system

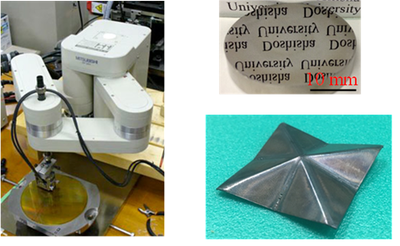

*Mecatoronics technologies for automation of traditional skill (polishing, origami process etc.)

*Green products and its design made by fine bamboo fibers extracted by computer numerical controlled end-mill tool, considering LCA (Life Cycle Assessment) and AI technologies.

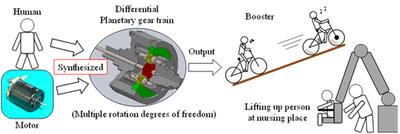

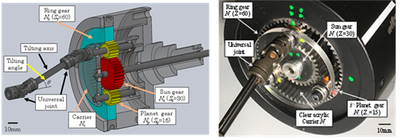

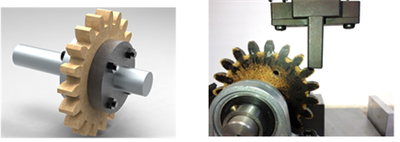

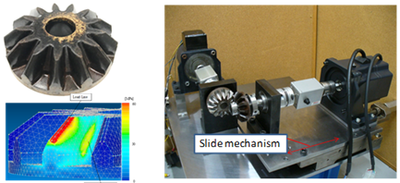

(3) Design and control of noise and vibration for transmitting mechanism to cooperate human and machine operation.

*Complex power driving system under many input and output sources with a differential planet gear mechanism

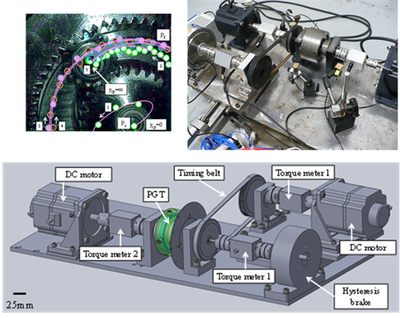

Developed test device for estimating a differential planet gear train and monitoring a planet gear motion with an image processing

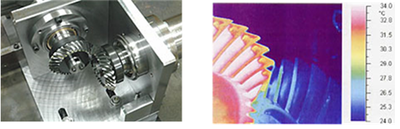

*Monitoring and estimating method based on infrared image processing

*Development of novel green organic mechanical elements and gears made of bamboo fibers

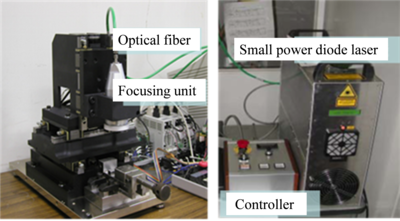

(4) Machine tools technologies for downsizing products and novel process monitoring methods for intelligent

manufacturing system

*Development of novel machine tools to manufacture mobile information terminal for connecting industries and

societies in IoT (Internet of things).

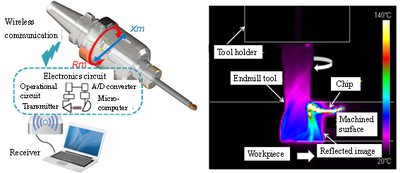

*Process monitoring methods based on wireless communication system, infrared image and high speed camera image

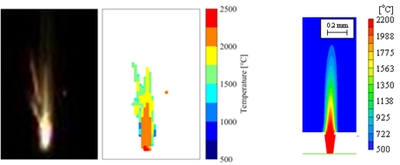

Estimation of temperature distribution with a two collar method from high speed camera image and its simulation with CFD (computational fluid dynamics)

Keywords

- Manufacturing System

- Design System

- Computer Numerical Control

- Machine Tools

- Industrial Robots

- Automation

- Life Cycle Assessment

- Machining Process Control

- Green Products

- Monitoring technology

- CAM

- Mechatronics

- Sustainability

- AI (artificial intelligence)