Graduate School of Science and Engineering Applied Chemistry

- Course Outline

- Electrochemical Laboratory

- Laboratory of Physical Chemistry

- Polymer Chemistry Laboratory

- Laboratory of Inorganic Synthetic Chemistry

- Functional Organic Chemistry Laboratory

- Laboratory of Catalysis and Material Design

- Laboratory of Biofunctional Chemistry

- Powder Technology Laboratory

- Transport Phenomena Laboratory

- Biochemical Engineering Laboratory

- Separation and Detection Chemistry Laboratory (Analytical Chemistry Laboratory)

- Molecular Chemical Engineering

- Material System Laboratory

- Biosensing Laboratory

Transport Phenomena Laboratory

Staff

TSUCHIYA Katsumi

[Professor]

| Acceptable course | |

|---|---|

| Master's degree course | ✓ |

| Doctoral degree course | ✓ |

Telephone : +81-774-65-6625

ktsuchiy@mail.doshisha.ac.jp

Office : SC-425

Database of Researchers

ISHIDA Naoyuki

[Professor]

| Acceptable course | |

|---|---|

| Master's degree course | ✓ |

| Doctoral degree course | |

Telephone : +81-774-65-6626

naishida@mail.doshisha.ac.jp

Office : SC-426

Database of Researchers

Research Contents

<1> Preparation and reaction mechanism of fine particles

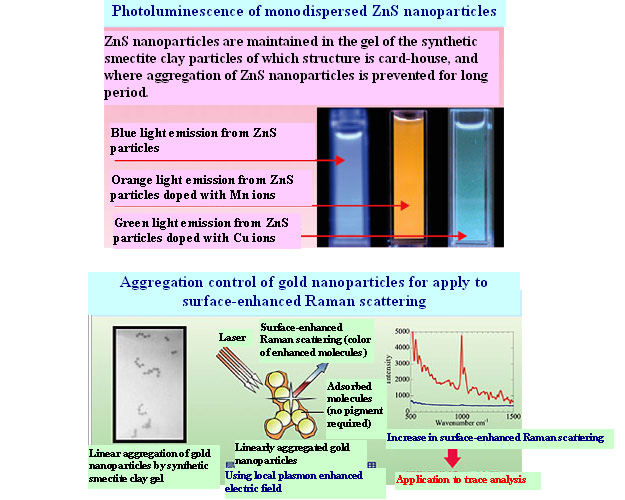

We conduct basic studies on the precipitation process of fine particles where molecules aggregate in solution by transport phenomena (diffusion, flow, etc.), and finally become particles through clusters or nuclei (phase transition). We consider to not only the solute concentration or the solution temperature but also the reaction field itself and external force field as parameters of the reaction mechanism. The micelles or reverse micelles which are the spontaneous association of surfactant in an aqueous solution or organic solvent, and the gel formed from polymers or clay particles are investigated as the reaction field during the preparation process of metal, ceramic, or polymer particles. We also examine the particle formation using the electric or ultrasonic fields as the external force field.

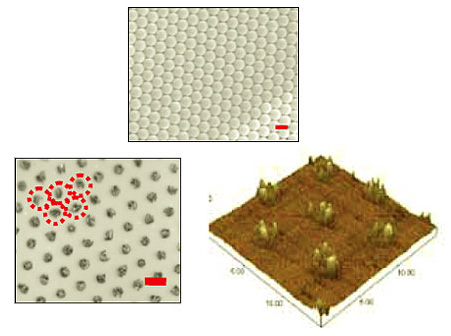

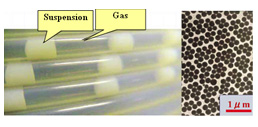

<2> Particle assembly for functional materials

Particle assemblies for functional materials are investigated using advective flow and external field such as electrostatic or vibrational fields. Monolayer ordered particle assembly of polystyrene latex (PSL) particles was formed on the glass plate using the continuous coating operation controlled by interaction forces among particles and between particles and a glass plate, as well as the operation conditions such as the advective flow rate, drawing speed of the plate, and feed rate of particle suspension. As the application of this assembly, we demonstrated to make the dots array prepared by gold nanoparticles, which we expect to apply the substrate for surface-enhanced Raman scattering. We also try to make the electrode of titania nanoparticles for dye-sensitized solar cell by using electrophoresis.

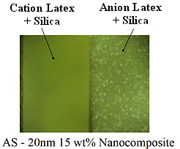

<3> Fabrication of nanocomposites

There are three types of composite materials; that is metal, ceramic and polymer system. And there are two types of polymer composite systems; where fibrous materials or fine particles are added as additives. The well dispersed state of the additives is very important for the performance of nanocomposite of polymer system, especially when the size of the additives decreases to submicrometer or nanometer order. We are examining methods how to disperse nanoparticles in polymers, and working on the development of methods for evaluating the particle dispersion state.

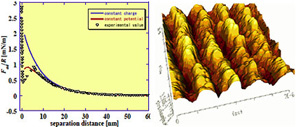

<4> Measurement of fine particle size and interaction forces between solid surfaces

In the research on nanoparticles and fine particles, the particle size is one of the most important characteristics to know the actual physical quantity. Another important characteristic in colloid research field is the evaluation or the calculation of the interaction forces acting among particles or between particles and other solid surfaces, because these interaction forces could control particle dispersion and aggregation behavior. We study these research topics in detail using various analytical equipments, where they are very fundamental topics, but the outcoming results will be extremely important.

<5> Formation of particles by continuous synthesis operation

Electrostatic atomization and tubular flow reactor methods are used to produce particles with uniform size, but the mechanisms of particle formation are not clear yet. We are examining the effect of various operating conditions, specifically when producing silica particles from sodium silicate aqueous solution and when preparing alginate gel from alginate aqueous solution. We are also examining operations to control the distribution of residence time in flow reactors with the aim of producing silica monodispersed particles.

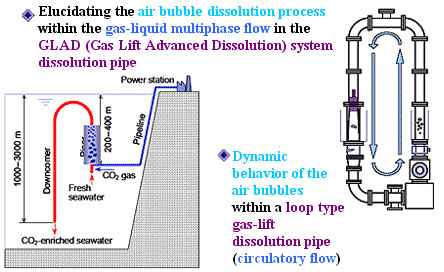

<1> Global warming strategy: removal and sequestration of atmospheric carbon dioxide

Global warming and the resulting climate change are major issues facing the global environment. High-efficiency ocean carbon dioxide fixation (Gas Lift Advanced Dissolution system, GLAD system) has been developed to combat this issue; it adeptly uses the properties of gas-liquid dispersed flow. We use "rapid visualization" to analyze the dissolution process of the air bubbles and the dynamic behavior of the air bubbles within the circulatory flow, with the aim of elucidating the gas dissolution process within the gas-liquid multiphase flow inside the GLAD system dissolution pipe.

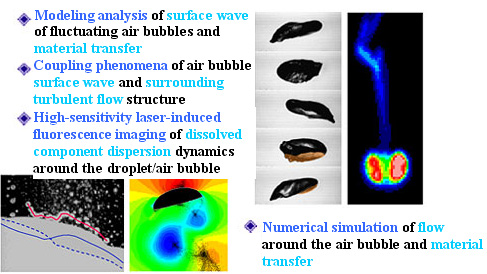

<2> Analysis and control of local interfacial transport properties in complex multiphase flow processes

We use "Visualization" and "Computational Fluid Dynamics (CFD) simulations" to analyze the complex dynamics engendered by interphase interaction. Specifically, we are creating methods to measure mass dispersion based on Laser-Induced Fluorescence (LIF) and ascertaining the state of mass dispersion around the interface using rapid/high-sensitivity fluorescent imaging with the aim of controlling the reaction based on quantification of the spatio-temporal distribution of concentration of the dissolved component as well as the local flow structure and concentration/dispersion pattern within the multiphase flow.

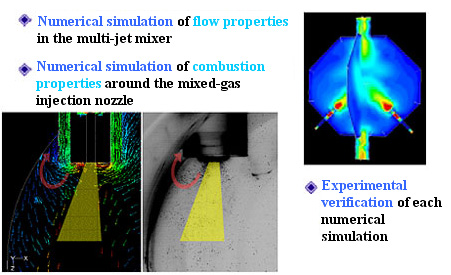

<3> Simulation of jet-induced gas mixing and combustion in reactors

We use "CFD simulations" to conduct numerical analysis of the flow, mixing and reaction of the mixing dispersion when multiple gases of different reactivity (e.g. high temperature/low temperature) are injected into the reactor, and we compute a design for the mixing process including the mixed-gas injection nozzle by different methods of introducing gasses and under different operating conditions. We also conduct cold model analysis using "flow visualization" to research the optimum design for the mixing process.

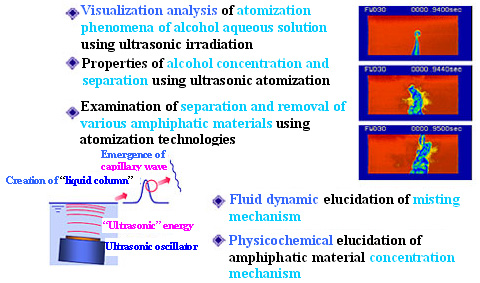

<4> Development of energy-saving separation process for volatile organic compounds using ultrasonic atomization

As opposed to universal separation processes such as those that use distillation columns, we are working on the development of an advanced separation process for organic solvents including alcohols and other amphiphatic compounds suitable for use in high-mix low-volume manufacturing (when there is limited facilities space, or short production lead time). More specifically, we are working on the production of "temperature-seal type single-pass ultrasonic atomizing separator" and conducting performance evaluation of this separator. In addition, we are looking at the separation and removal of various organic compounds using this atomization technology, with the aim of establishing this as one of environmental technologies.

<5> Evaluation of transport and fractionation of fine particles through microchannels

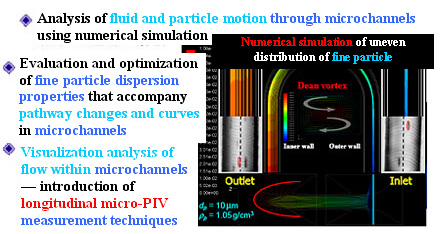

To control the basic properties (particle size, dispersion, etc) of fine particle transport required for aggregation of fine particles, we need to establish evaluation techniques including the distribution of the liquid phase flow rate, the fine particle pathways, and the interaction between fine particles to elucidate the properties of fine particle transport and fractionation that accompany pathway changes and curves. To this end, we use "CFD simulation" to analyze fluid and particle motion through microchannels, leading to guidelines for the design of microchannels. Based on this, we will produce a prototype, and use "longitudinal micro-PIV measurement techniques" to conduct "high-resolution, rapid visualization" analysis of fine particle transport and fractionation phenomena in the channel flow field.

Keywords

- Transport phenomena

- Fine particle formation

- Nanoparticle

- Reverse micelles

- Gelation

- Sonochemistry

- Particle size distribution analysis

- Force between surfaces

- Particle ordering

- Monodispersed particles

- Optical properties of fine particles

- Gas-liquid-solid dispersed flow

- Controlling global warming

- Carbon dioxide

- Bubble dissolution

- Multiphase flow

- Gas-liquid interface

- Mass dispersion

- Flow visualization

- CFD simulation

- Gas mixing and combustion

- Ultrasonic atomization

- Microchannels

- Fine particle transport and fractionation

- Micro PIV