Graduate School of Science and Engineering Applied Chemistry

- Course Outline

- Electrochemical Laboratory

- Laboratory of Physical Chemistry

- Polymer Chemistry Laboratory

- Laboratory of Inorganic Synthetic Chemistry

- Functional Organic Chemistry Laboratory

- Laboratory of Catalysis and Material Design

- Laboratory of Biofunctional Chemistry

- Powder Technology Laboratory

- Transport Phenomena Laboratory

- Biochemical Engineering Laboratory

- Separation and Detection Chemistry Laboratory (Analytical Chemistry Laboratory)

- Molecular Chemical Engineering

- Material System Laboratory

- Biosensing Laboratory

Powder Technology Laboratory

Website of the Laboratory 【In Japanese and partly in English】Towards creation of intelligent powder systems and processes using powder experiments and simulations

Staff

SHIRAKAWA Yoshiyuki

[Professor]

Dean

| Acceptable course | |

|---|---|

| Master's degree course | ✓ |

| Doctoral degree course | ✓ |

Telephone : +81-774-65-6596

yshiraka@mail.doshisha.ac.jp

Office : SC-326

Database of Researchers

YOSHIDA Mikio

[Professor]

| Acceptable course | |

|---|---|

| Master's degree course | ✓ |

| Doctoral degree course | |

Telephone : +81-774-65-6608

miyoshid@mail.doshisha.ac.jp

Office : SC-408

Database of Researchers

Research Topics

- Optimum design and control methods for powder processes

- Controls of particle flow and cohesive behaviors by admixing smaller particles

- Design of aggregated nanoparticles and their dispersion operations

- Synthesis of composite particles by using a non-uniform nucleation for pharmaceutical and cosmetic applications

- Synthesis of composite and amorphous materials by using mechano-chemical methods

Research Contents

We use powder experiments and simulations, to conduct research on the production of high-function materials and powder processes involving powder particles and on the design of powder particle systems. In particular, we introduce the concept of systems engineering to create optimum designs for high-function powder materials formed by the aggregation of numerous particles with varying chemical compositions, the production processes for these materials, and the devices that use these materials.

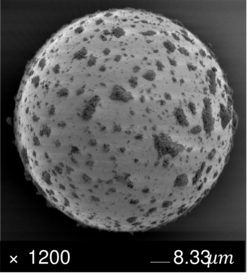

A SEM image of TiO2 porous hollow particles

contained vitamin C

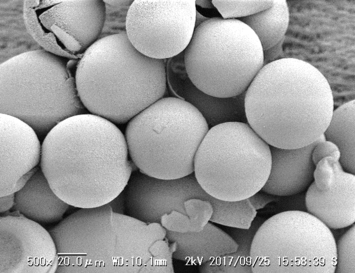

A SEM image of surface structures for improving

particle flowability

Keywords

- Powder properties

- Chemical simulations (MC and MD)

- Particle simulations

- Slurry dispersion

- Adhesive force of particle

- Particle Flowability

- Mechano-chemical reactions

- Composite particles

- Crystallization